Number of times:419次

Type of commodity:PRODUCT

Shelf time:2024-04-12 14:02:20

Product description:1.Features:①It has excellent thixotropy and leveling properties, and the coating has no brush marks.②It has good suspension stability and is easy to operate a···

Telephone Enquiry:+86 132 1052 0517

whatsapp 8618254144249

Email:zoro@chishuogroup.com

1. Features:

①It has excellent thixotropy and leveling properties, and the coating has no brush marks.

②It has good suspension stability and is easy to operate and use.

③The gas generation volume is small, which can reduce the occurrence of pore defects in castings.

④After the paint dries, the coating will not crack or blister, and has high strength at room temperature.

⑤It has good resistance to sand sticking, the surface of the casting is smooth and easy to clean.

⑥This coating is easy to transport, safe to store and has a long shelf life.

2. Scope of application:

Suitable for lost foam process include ductile iron castings , gray iron castings and steel castings.

3. Package: This product is packed in woven bags, 40 kg per bag.

4. Generally, castings can be brushed once or dipped . Thick and large parts and areas prone to sand can be brushed or dipped twice.

Note: The brushing or dipping area should not be too large at one time, otherwise it will affect the quick-drying effect.

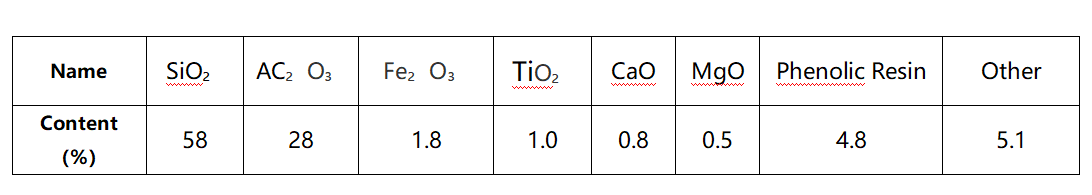

5. Main ingredient content:

Introduction of Alcohol Based Powder Lost Foam Coating

1. Method of application:

①This alcohol based powdery lost foam coating needs to be diluted and stirred thoroughly before use. The mixing speed of the paint mixer is required to be not less than 600 rpm.

②The industrial alcohol content used to dilute the paint is ≥98%.

a. Proportion of each component: Powder coating to industrial alcohol is 3∶(1.6-1.8).

b. Weigh the paint and alcohol in proportion; preparation process: turn on the mixer, add alcohol and dry powder paint in sequence, and stir for 50 minutes.

c. Check the Baume degree of the paint, and add an appropriate amount of alcohol to adjust the Baume degree of the paint. Make the coating meet the usage requirements.

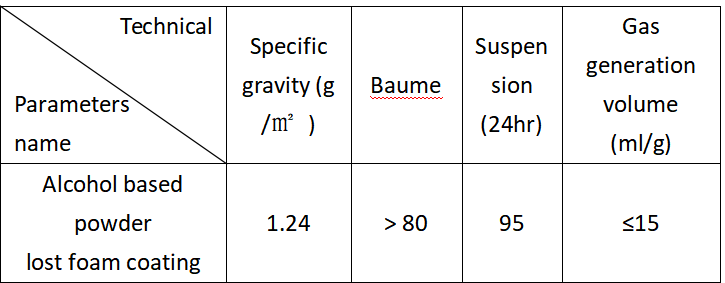

2. Technical parameters of slurry paint obtained after dilution:

3. Shelf life:

This product should be stored in a cool place. Shelf life is 1 year.

Introduction of Water Based Paste Lost Foam Coating

1. Method of application:

①This water based paste lost foam coating needs to be diluted and stirred thoroughly before use. The mixing speed of the paint mixer is required to be no less than 600 rpm.

②The paint dilution material is normal temperature water .

a. Proportion of each component:

Paste paint to normal temperature water is 2.5: (1.6-2.0).

b. Weigh the paint and room temperature water in proportion; preparation process: turn on the mixer, add room temperature water and paste paint in sequence, and stir for 50 minutes.

c. Check the Baume degree of the paint and add an appropriate amount of normal temperature water to adjust the Baume degree of the paint. Make the coating meet the usage requirements.

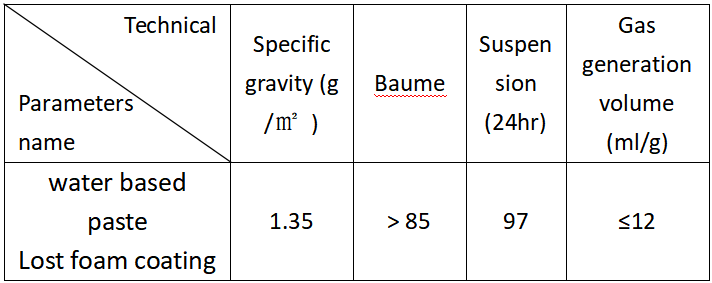

2. Technical parameters of slurry paint obtained after dilution:

3. Shelf life:

This product should be stored in a cool place . Temperature 0℃-25℃, shelf life is 8 months.